Project Brief

"Design and make an artifact that resolves a problem that you have defined."

Tools and Materials Used

Acrylic

Loop clamp

Nuts and bolts

Laser cutter

Prototyping: Paper

1) Problem & Prototypes

Daily, I bike to and from campus. Living in Pittsburgh, I often bike in the rain and end up with a soaked backside and a muddy backpack. I have yet to buy a splash guard for my bike since this situation does not occur often enough to motivate me to go out of my way to purchase and install a splash guard. However, since I have been given the opportunity to solve an every day problem, I decided to solve this problem of a wet backside by custom designing and producing a splash guard for my bike.

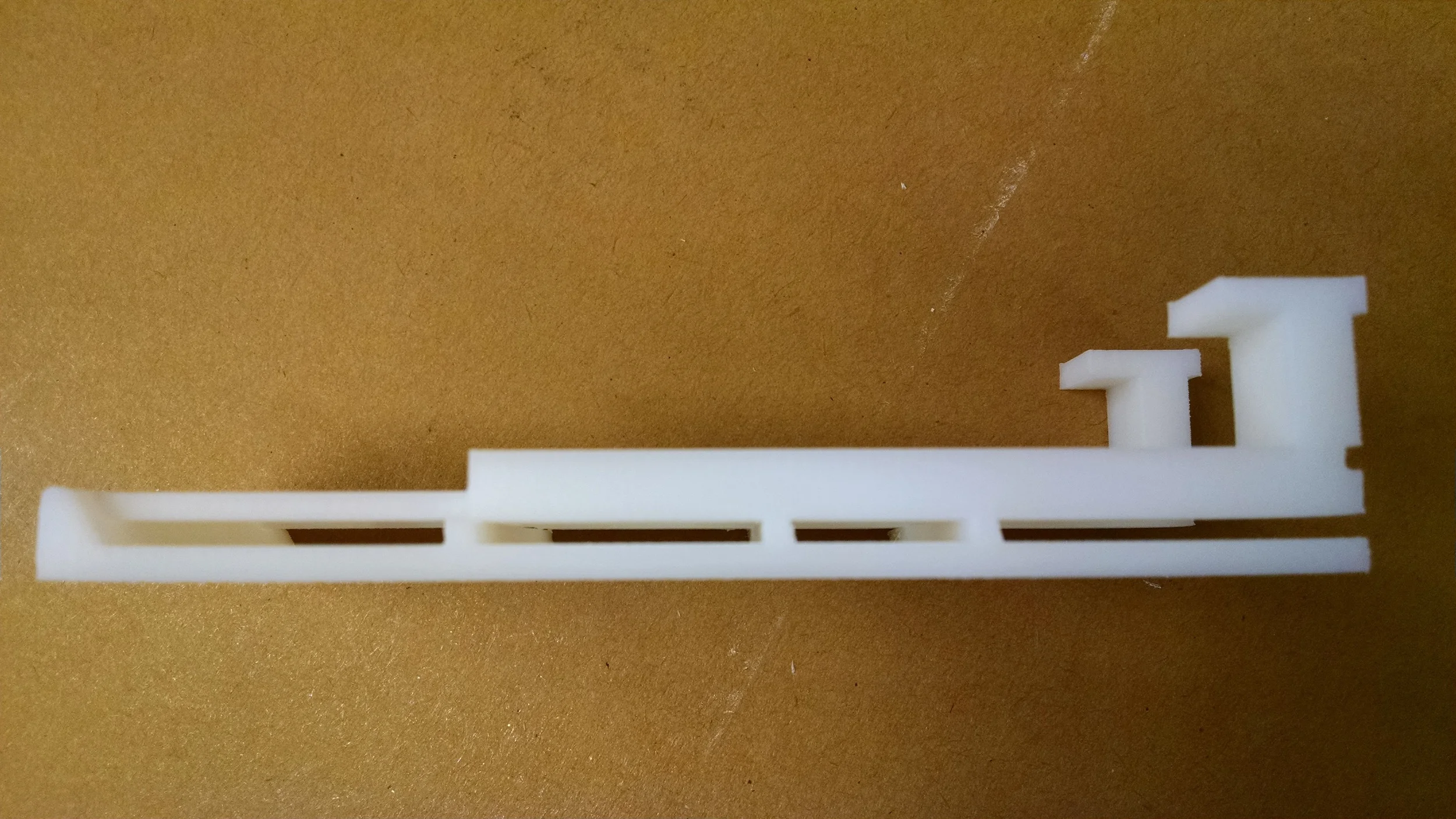

Since I have yet to study a splash guard in detail, I image searched bike splash guards to see the general size and shape of it. The most difficult part of designing the splash guard was finding a shape sturdy enough to cantilever. I used folding techniques instead of additive methods so that the shape would not rely on joinery methods to be structurally stable.

Studies:

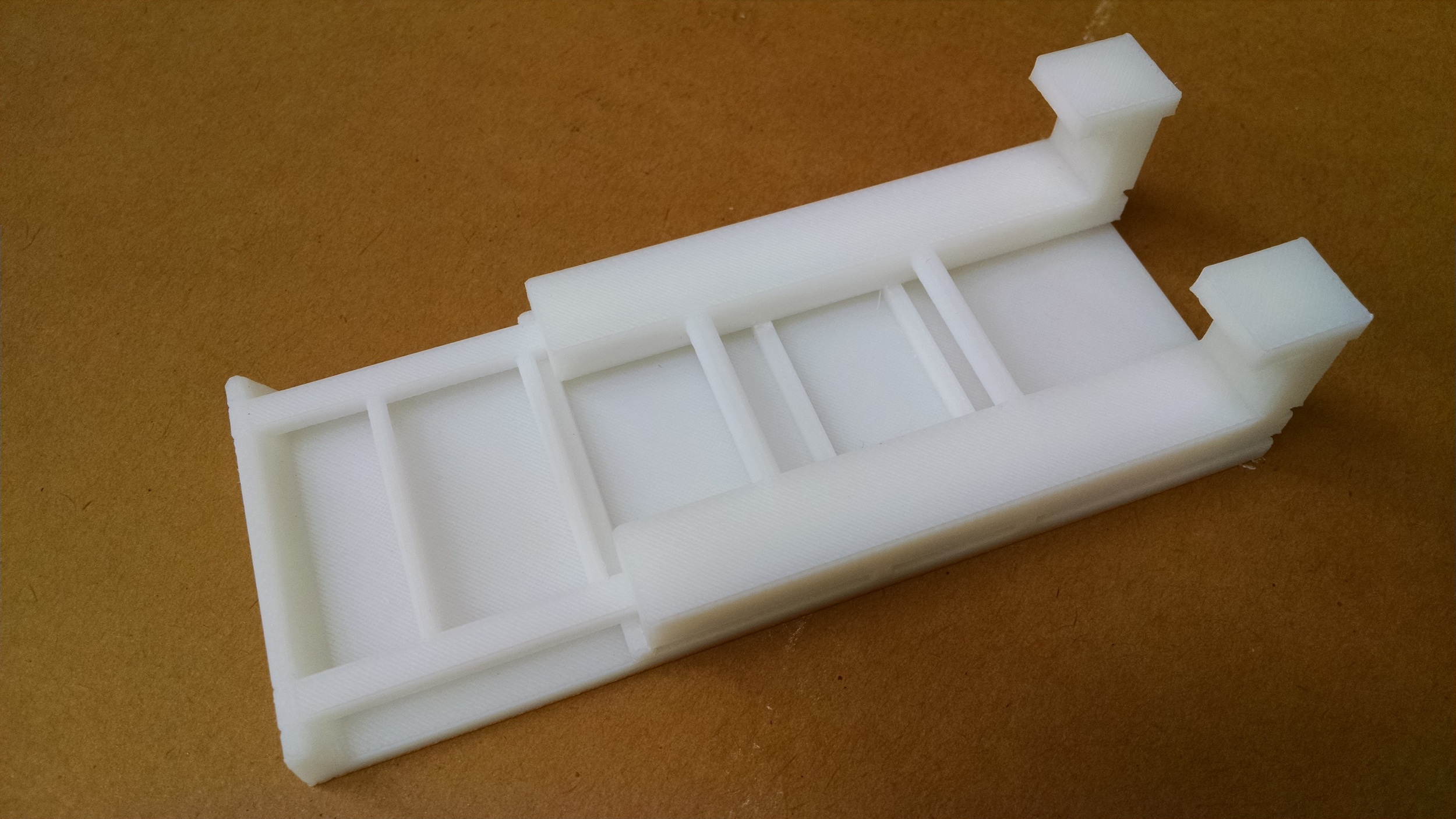

First Successful Iteration:

Final Paper Prototype:

Given the last iteration, I extended the length of the splash guard and made minor changes to accommodate the added length.