Project Brief

"Design and build a reconfigurable formwork within a 10" x 10" plaster tile."

Tools and Materials Used

MDF

Canvas

Wood dowels

Plastic: PETG, Polystyrene

Wax

Plaster

Vacuum forming

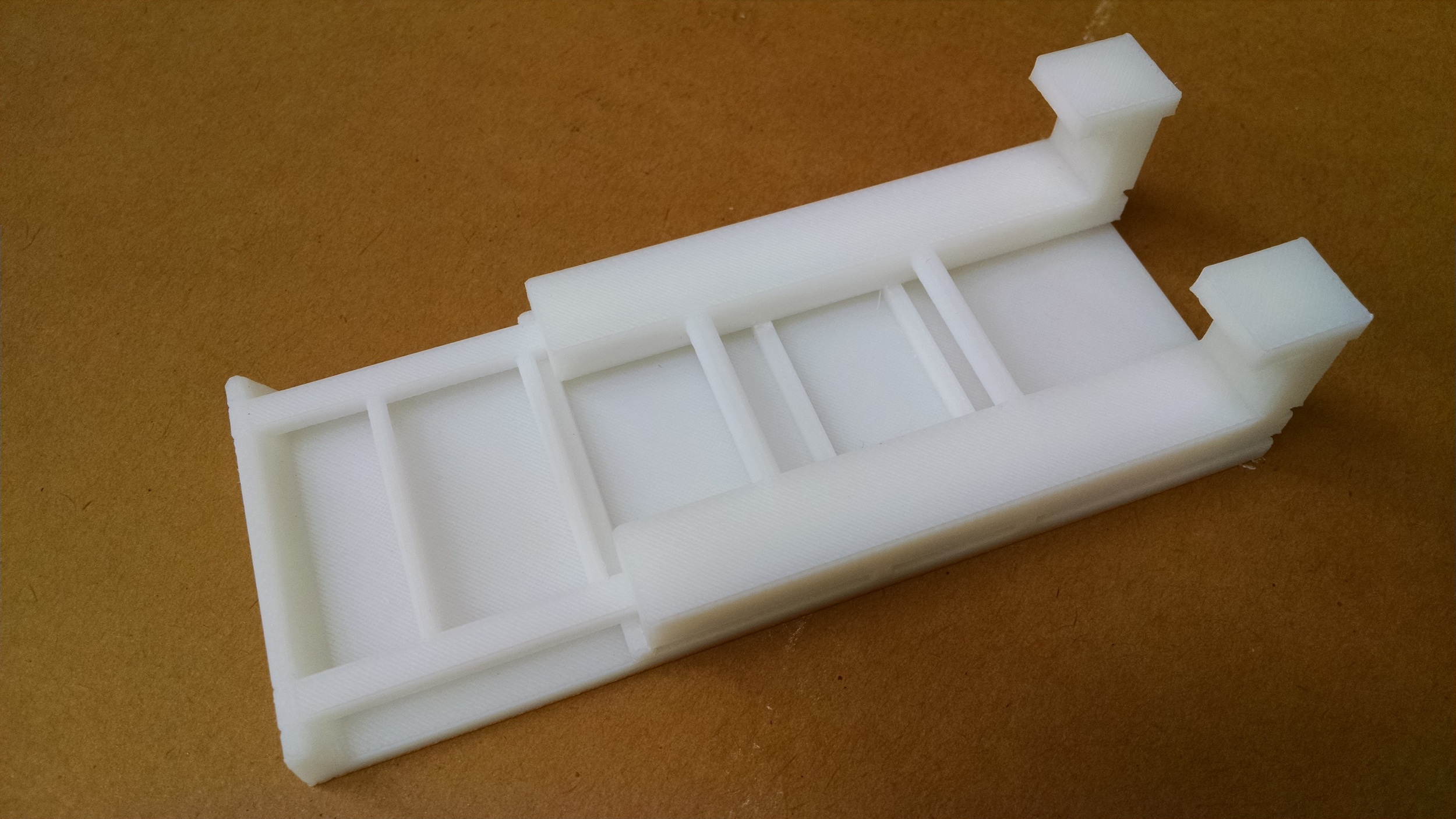

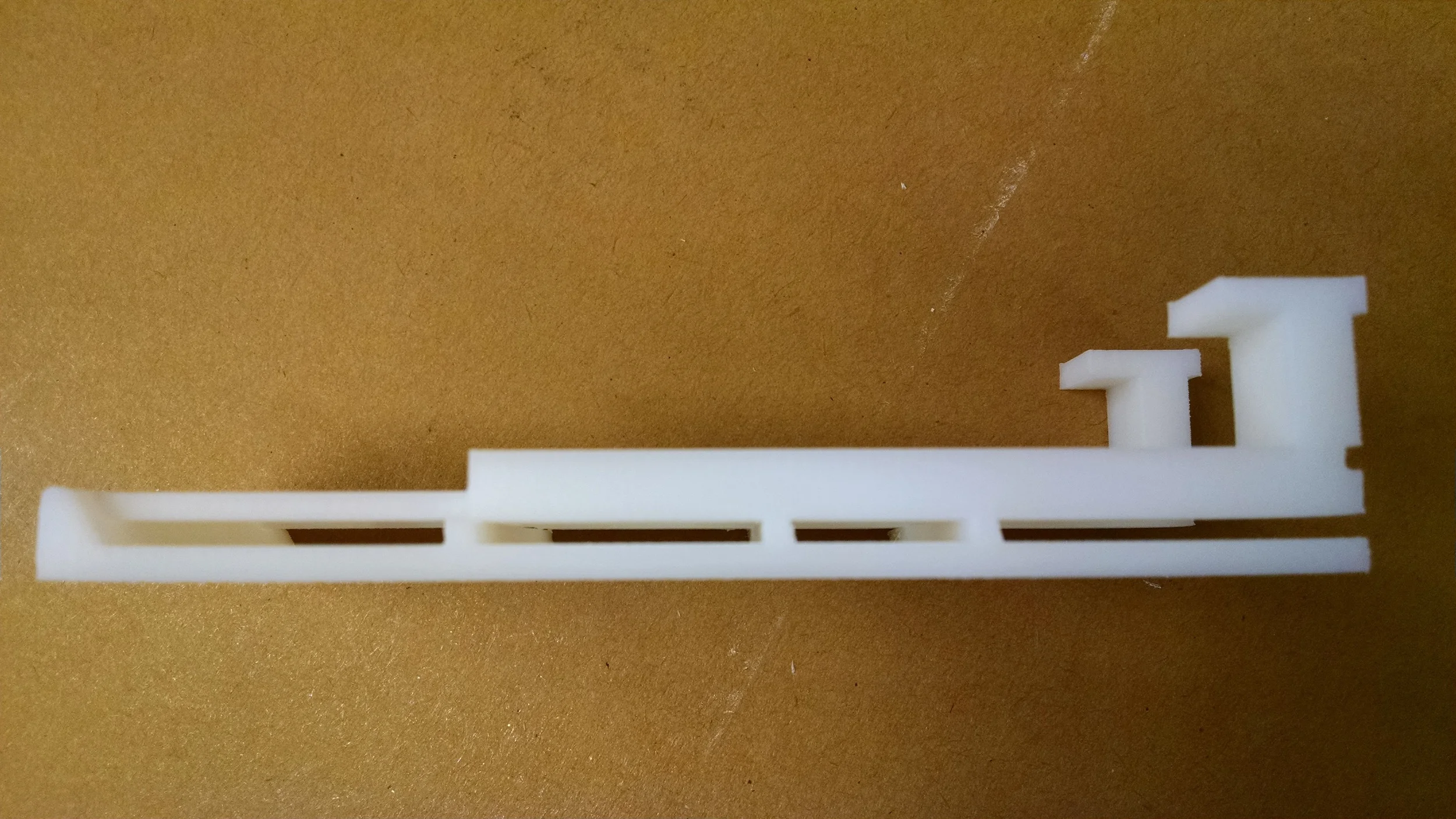

Obstacle 8

For this obstacle, I considered the spatial possibilities of the tile with a simple and modular design approach. I did not want to design the four tile variations and then create the different modules, but rather I allowed much room for improvisation and surprises.

Process Photos:

Final Photos:

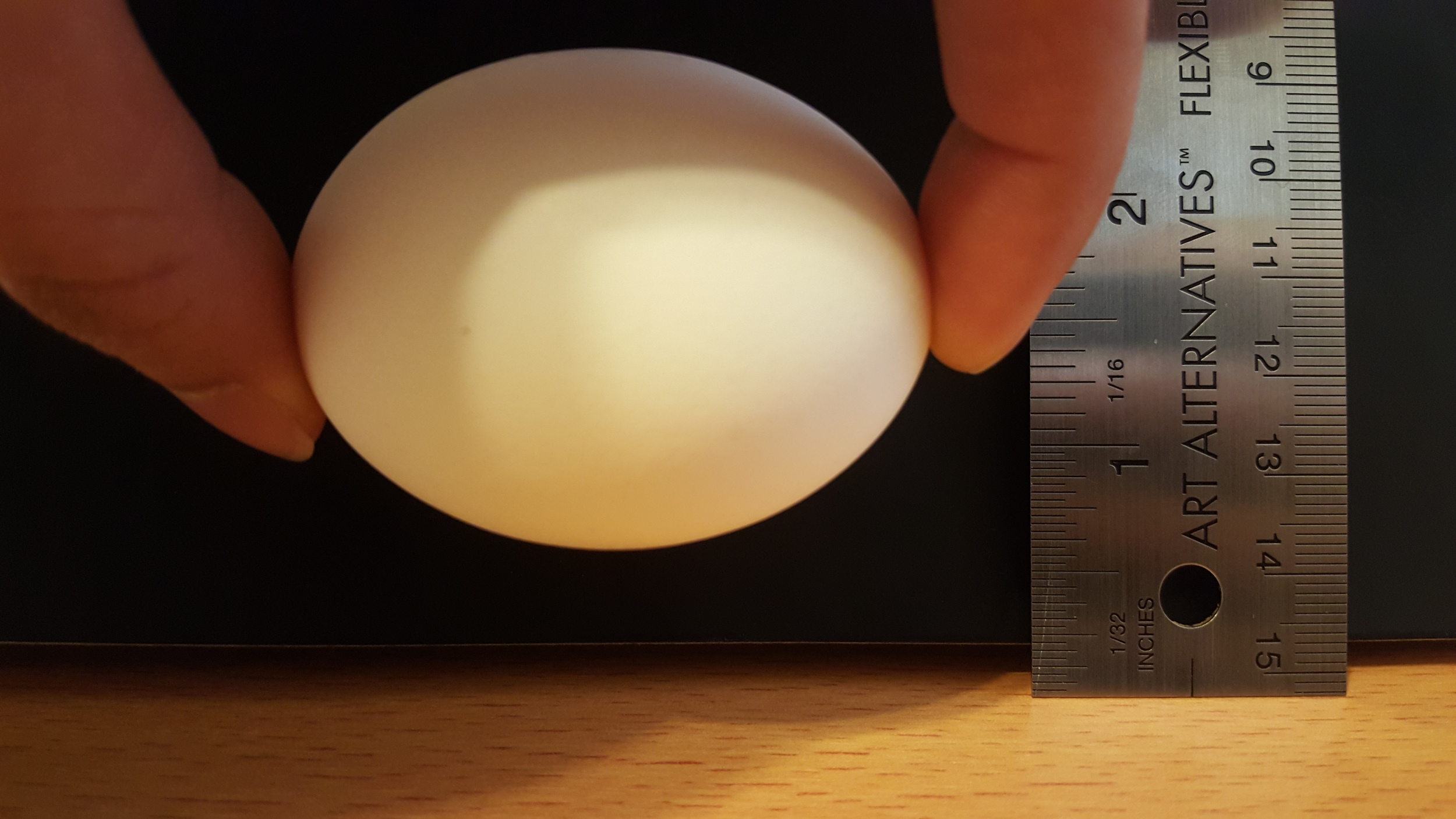

Obstacle 9

Plaster is usually not seen as a flow-y object. However, in its liquid state, it easily forms to the volume that it is poured into. I wanted to display this form-fitting characteristic of plaster's liquid state once it had solidified. I chose to use canvas as the material for the mold in hopes the texture would translate onto the plaster.