Project Brief

"Design a personal identity mark."

Tools and Materials Used

Rhinoceros

Laser cutter

Rubber

Wood - Cherry, Brazilian Walnut

1) Logo Designs

Although there was encouragement to go beyond using our names as driving factors for the logo designs, I wanted the stamp design to be general and formal for other possible uses beyond this class. I explored different ways of representing my name, and I first started with a more creative and free-thinking approach, inspired by graffiti tags. The next two utilize all the unique letters in my name: A, R, L, and E. The bottom center logo is the abstracted version. The last two are my initials, and are the logos that I had originally designed a few years back for my portfolio website. I lean towards these two as they are clean, simple, and generic.

2) Fabrication

I spent a significant time figuring out the best laser cut setting for cutting and engraving on the rubber. I did multiple tests to see how certain settings would affect the result. I started out with a recommended setting I found online, and made changes accordingly to deepen the engraving or to limit the burning of the cut.

First Tests

[Stamp Default Settings]

[Raster Setting] Speed 40, Power 40 \\ Default numbers

[Vector Setting] Speed 15, Power 100 \\ Not pictured

[Raster Setting] Speed 40, Power 55 \\ Power increased for deeper engraving

[Vector Setting] Speed 12, Power 100 \\ Previous cuts did not go through

[Raster Setting] Speed 30, Power 75 \\ Speed lowered and power increased

[Vector Setting] Speed 12, Power 70 \\ Still too much burning

[Result] No rastering occurred, and "fences" were ignored. I quickly abandoned the stamp setting on the laser cutter.

[Result] The depth of the engraving seemed to shallow.

[Result] I was still not satisfied with the depth of the engraving, and the cuts could use less burning around the edges.

[Result] The engraving was too deep, and cuts were still burning too much.

Final Setting

[Raster Setting] Speed 40, Power 80 \\ Higher speed prevented burning

[Vector Setting] Speed 20, Power 60 \\ Good depth for stamping

[Result] Final rubber cutouts for one logo design

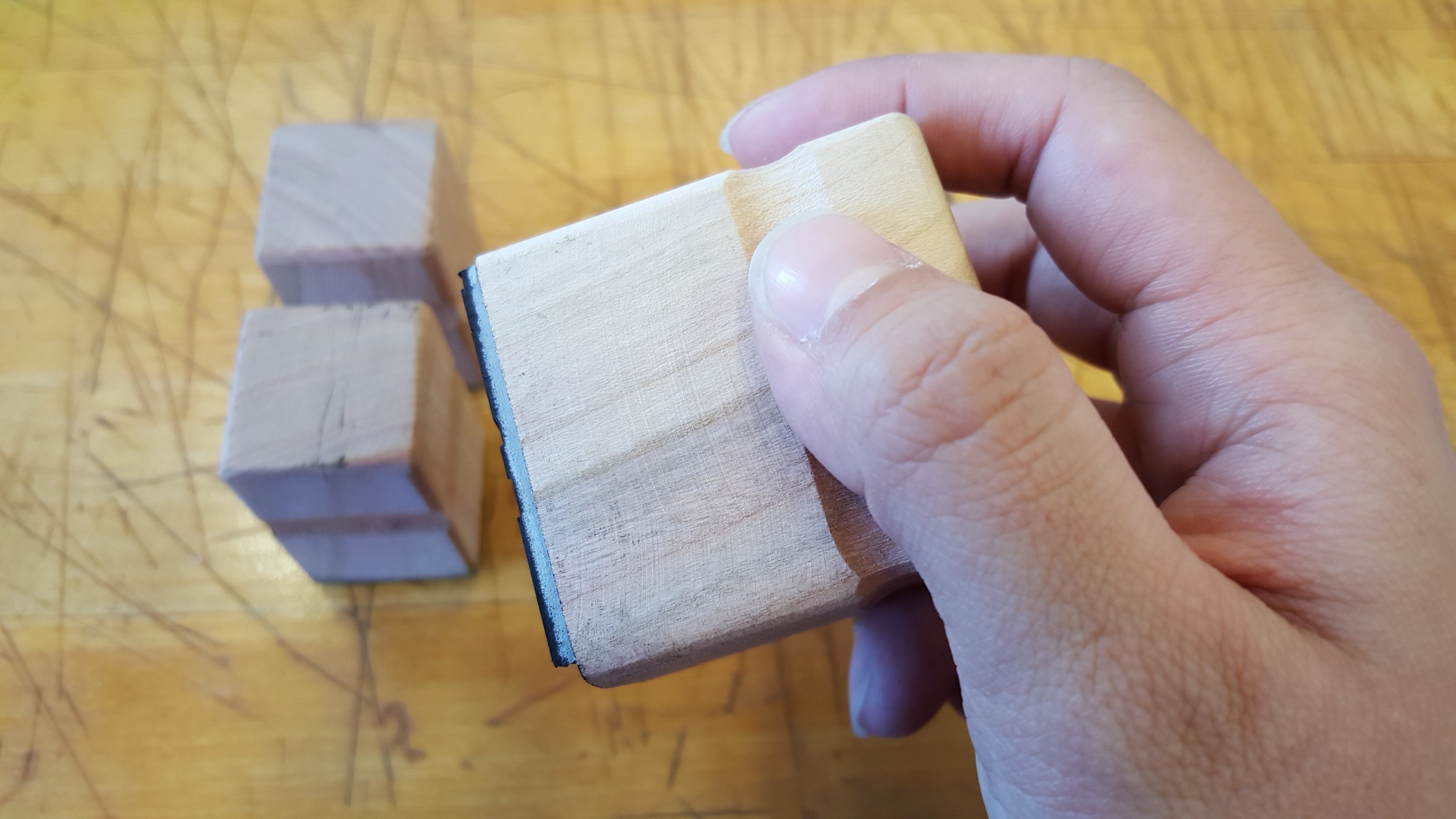

Final Product

The stamp handles were made in wood shop, and the grooves were made on the oscillating spindle sander.

Outcome

Rubber Cut Sheet

Stamp Top

Stamp Bottom

Groove for Grip

![[Stamp Default Settings]](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454106254496-10A14Z9F23G8870UOES3/image-asset.png)

![[Raster Setting] Speed 40, Power 40 \\ Default numbers[Vector Setting] Speed 15, Power 100 \\ Not pictured](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454602859984-QQC4ECDCYH5J3DPNSVA3/image-asset.png)

![[Raster Setting] Speed 40, Power 55 \\ Power increased for deeper engraving[Vector Setting] Speed 12, Power 100 \\ Previous cuts did not go through](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454603605397-VNIK046E7IF8GO0IR1OW/image-asset.png)

![[Raster Setting] Speed 30, Power 75 \\ Speed lowered and power increased[Vector Setting] Speed 12, Power 70 \\ Still too much burning](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454604475848-FI0N3BDMG2CD3IGFW6JT/image-asset.png)

![[Result] No rastering occurred, and "fences" were ignored. I quickly abandoned the stamp setting on the laser cutter.](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454107138100-WIFDIE1SHTJIT0KK6G6U/image-asset.jpeg)

![[Result] The depth of the engraving seemed to shallow.](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454603146499-RXH31VRE46P8Y08JEUCB/image-asset.jpeg)

![[Result] I was still not satisfied with the depth of the engraving, and the cuts could use less burning around the edges.](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454603621086-SGO2ZB8JELIJCGYETIDO/5_-.jpg)

![[Result] The engraving was too deep, and cuts were still burning too much.](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1454604491927-VD4TXJ0XE3RRP8TIE3PY/image-asset.jpeg)

![[Raster Setting] Speed 40, Power 80 \\ Higher speed prevented burning[Vector Setting] Speed 20, Power 60 \\ Good depth for stamping](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1456407063480-SAJY63ARWNZA6TLSECYZ/8_final.PNG)

![[Result] Final rubber cutouts for one logo design](https://images.squarespace-cdn.com/content/v1/54160f7ce4b0ee57f83f7917/1456407219603-BVDOYQPY54CIFOCCRH53/image-asset.jpeg)